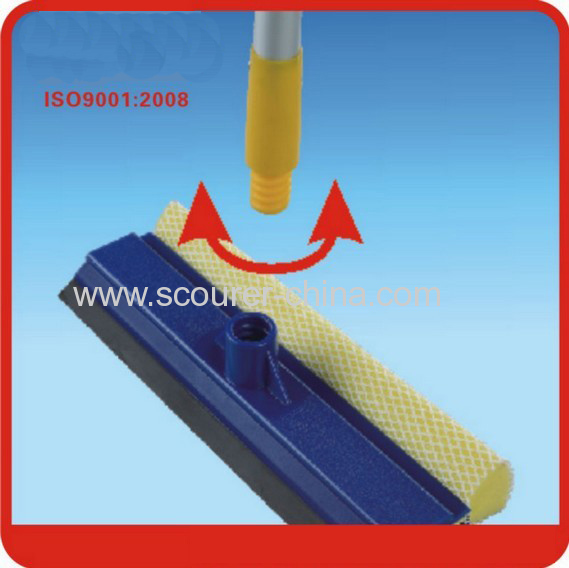

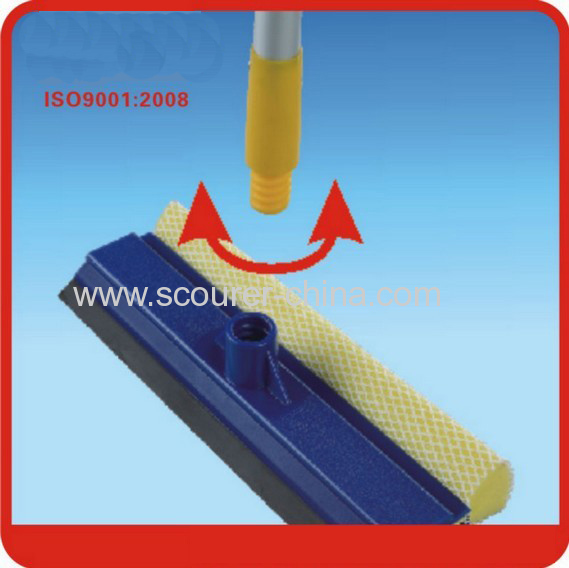

Safety Detachable Multi-functional window cleaner Blue& yellow Color

Specifications

Multifunctional window cleaner

1. Is made of Aluminium and pp etc.

2. Multi-functional for glass cleaning.

3. The replaceable sponge provides protection against surface damage,durable and removes dirt easily.

4. The rubber blade has good flexibility and can remove water & dirt easily.

5. Widely used in smooth surface such as glass.

6. Telescopic alu handle can reach height area available.

7. Is good helper for your life.

| Item No | MC20-1233-11 |

| Material | Sponge,ABS,aluminum,rubber |

| Size | 20cm |

| Packing | Color card |

| Ctn size | 51*23*25 /24pcs |

| 20ft | 21672 pcs |

| 40ft | 45816 pcs |

| 40HQ | 53184 pcs |

Safety Detachable Multi-functional window cleaner Blue& yellow Color

Safety Detachable Multi-functional window cleaner Blue& yellow Color

Product introduction:

Coated water device, is the most commonly used glass cleaning tools. The T word frame and coating water apparatus hair set of combination and become. Coated water apparatus hair set have superfine fibre cloth, sunny Aaron into cloth, water absorption is strong, not easy and wool, have very strong friction cleaning ability. Only need to slap on the cleaner, gently rub, glass dirt was immediately cut through wet separation processing, then use glass scraping, immediately let glass crystal, crystal, T frame structure into design, graceful appearance, beautiful and easy, the impact resistance material production, durable.

Product index: coated water machine, glass cleaner, burr, T frame coating water apparatus hair sets, glass cleaning burr, glass cleaning with water machine, glass cleaning tools.

Multi-functional window cleaner 20 cm Size Color card

Product features:

1, Durable parts base using advanced materials, use special weave, and strengthen treatment, with products durable, is not easy to rust;

2, The feather eye Aaron, superfine fiber materials, water absorption is strong, not easy and wool, T word frame with advanced coating water apparatus hair set, day to close match.

3, Removable combination, easy to carry,

Method of use:

1, Coated water machine before use must be clean and free from contamination.

2, Will be coated water apparatus in the clean liquid in the water and pulled out by hand * once, to drop down so far.

3, Will be coated water apparatus on the glass or building decoration materials hard on the surface, pay attention to four edges and corners, not leak wipe.

4, Can erase dirt, can be used with water apparatus clear.

5, Coated water device when use, cleaner or wipe of the sewage shall not produce splash, lest cause secondary pollution.

6, After use, timely cleaning with water apparatus cover, air inactive, and properly keep coated water machine frame and set aside.

Multifunctional window cleaner Popular products for Europe

Packaging & Delivery

| Packaging Details: | Paper card ; 24pcs /ctn ;0.029m3 |

|---|

| Delivery Detail: | 30 -35 days after we receive deposit. |

|---|

Quick Details

- Usage: Window.

- Handle Material: Aluminum.

- Feature: Eco-Friendly,Stocked.

- Place of Origin: Zhejiang, China (Mainland).

- Brand Name: MASTER CLEAN& OEM

- Model Number: MC20-1233-11

- Color: blue&yellow.

- Size: 20 cm.

- Handle: telescopic aluminum handle.

- Function: multifunctional.

- Packaging: color card.

- advantage: detachable.

- Style: popular products for Europe.

| In-process management procedures |

| 1.According to production requirements,logistics is resposible for establishing EHS requirements,rational layout of the production enviroment,production department to maintain the production according to 5S management requirements,to a special enviromental in equipment or procedures,need to have a formal document specify that the staff must strictly enforce,on the anti-static requirements of the process and location,must operate strictly in accordance with the guidance document and the corresponding documentation for operation. |

| 2.Engineering resposible for equipment maintenance, specific maintenance contents fefer to production equipment control procedures. |

| 3.Production resposible for assist materials control Department of the online materials,and manage scrap units. |

| 3.Production control production line output according to plans,use the "production internal maintenance form"record and track human,machines,materials and technics abnormity in produce process;quality control/Engineering Department make a patrol inspection on the production line to control the production process quality.According to the process and equipment characteristics,the production process will be devided into general process,key process,and special process for different levels of control. |

| 4.1 General process control |

| 4.1.1 Before production,should confirm raw materials preparation,equipment status,operation guide books,staff skills. |

| 4.1.2 Strictly operate in accordance with the guidance books,through the operator self-inspect,multi- inspect and QA patrol inspect for real-time monitoring quality. |

| 4.1.3 The feedback of fluctuate process:promote production management principles. |

| 4.1.4 The defective in prodction operate according to "Defective control procedue" |

| 4.1.5 Record and stat production status |

| 4.2 Key process control |

| According to product characteristics,the company confirm the fire detector calibration processes and functions of mobile detector test processes for key processes. |

| 4.2.1 Pre-production with the test samples could confirm whether the equipment used for the production and make records. |

| 4.2.2 Quality selective inspect of the fire detector sensitivity to control the accuracy of calibration. |

| 4.3 Special process control |

| According to product characteristics,the company confirm SMT,reflow solder,hands and wave soldering process for the special process and the specific special control refer to "special process control procedure". |

| 5.Production process should be operational by guide book guide,operation guide book shall be in writing in pictures combined description code,and pay attention items and quality standards. |

| 6.Quality records requirement in the process should follow the related contents of Record control procedure". |

| 7.After the end of production,after the inspection and acceptance by quality control,the packing storage,warehouse confirm quantities and arrange every lot intergated qualified products to meet the quantities request of shipment orders.If the inventory were stored for more than three months and need to ship,the materials control department supply appliactions,after the production rework,the inspector re-inspect,and passing inspection,then shipment. |

Professional supervision Loading

Carton Fair we've attended

Company Certificates

Workshops review:

Workshops review:

Company tenet:

With the mission of customers first,quality oriented,Ningbo Master Clean Commodities Co.,Ltd. pays special attention to technology innovation and quality stability,and offer best quality products and services to customers and clients warmheartedly to satisfy customers.